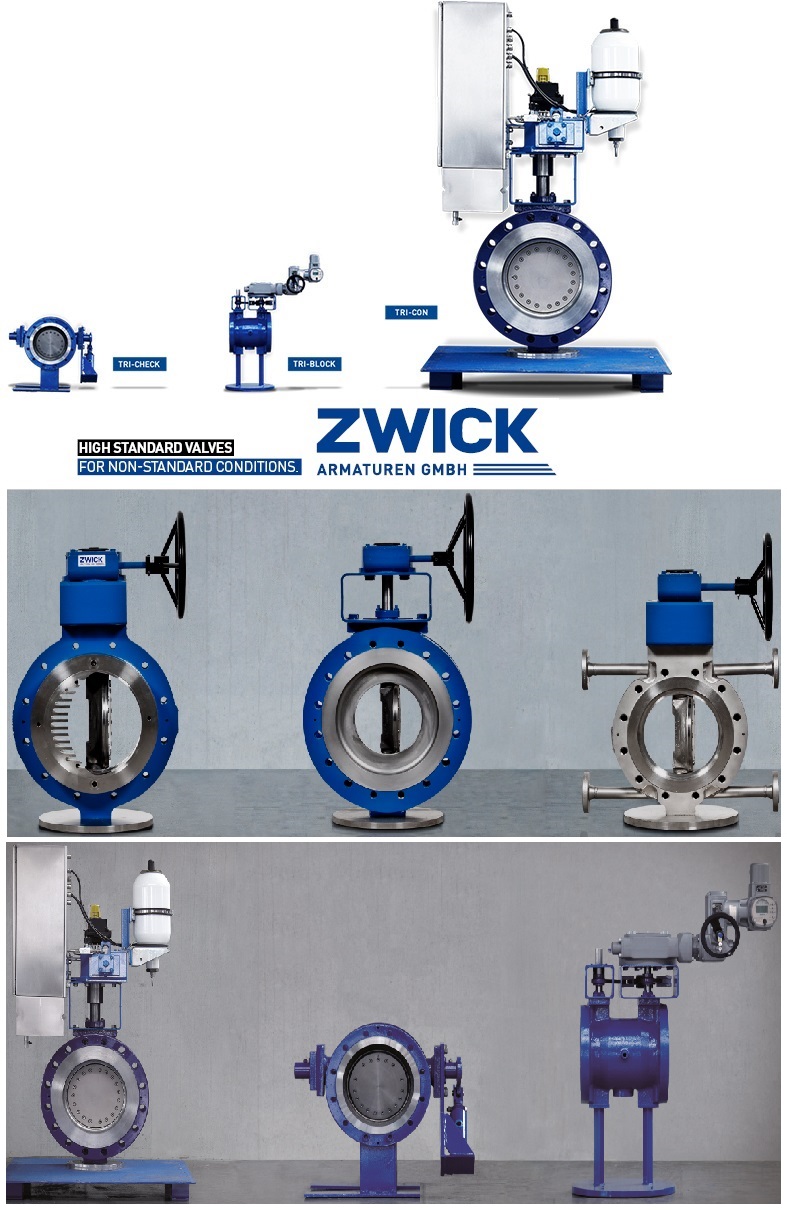

Products

Products

Triple offset butterfly valves ZWICK TRI-SHARK

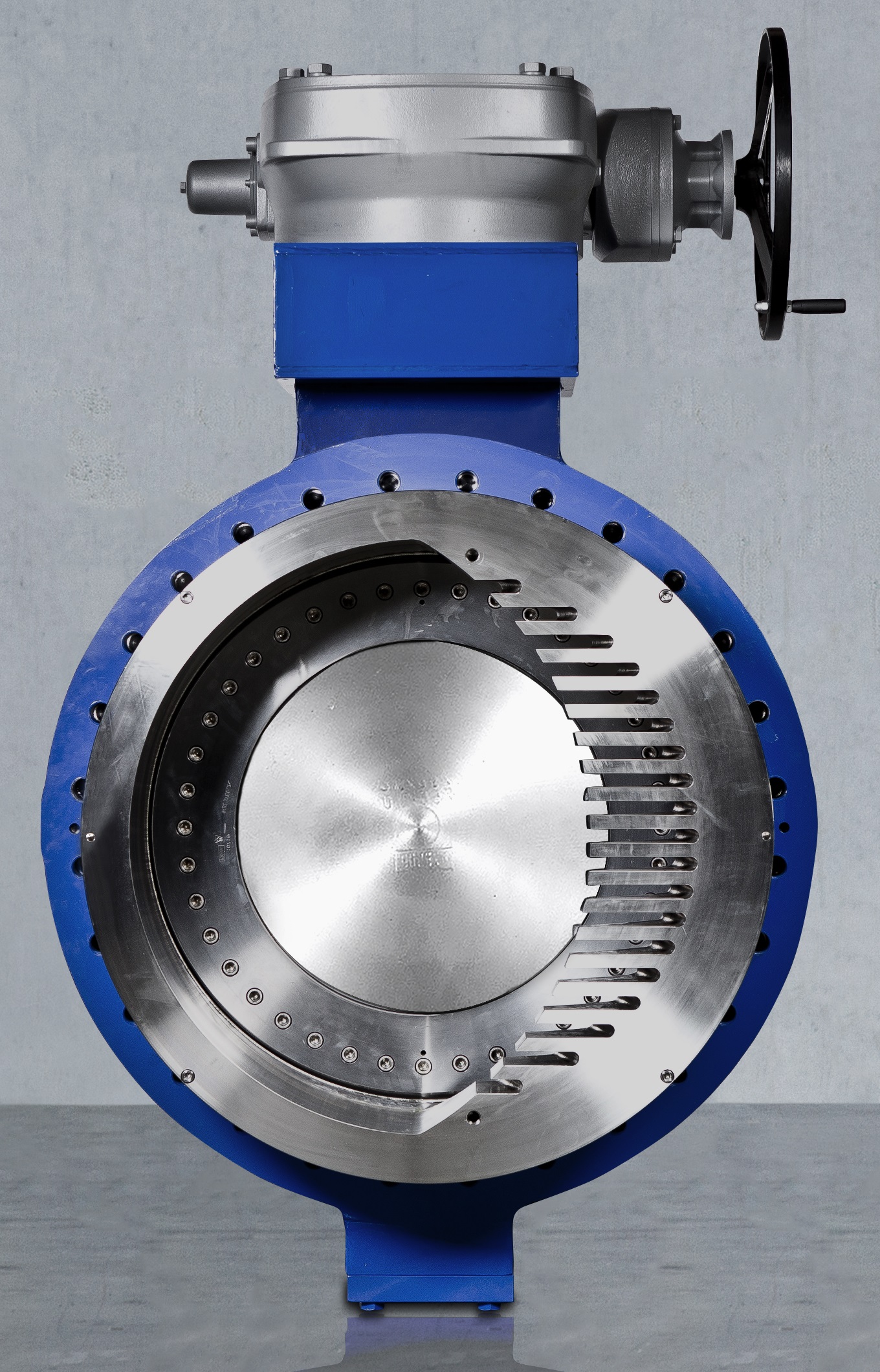

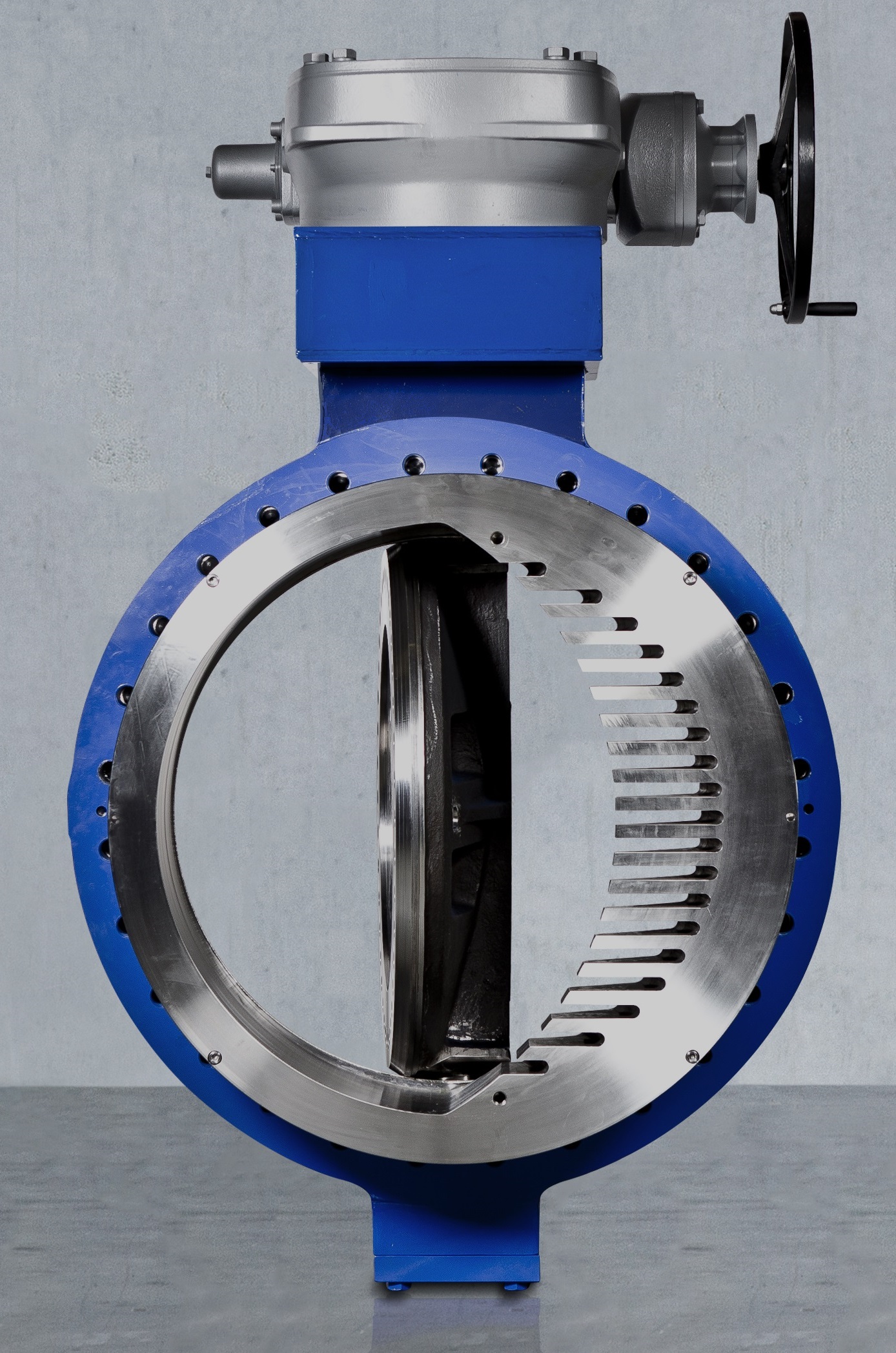

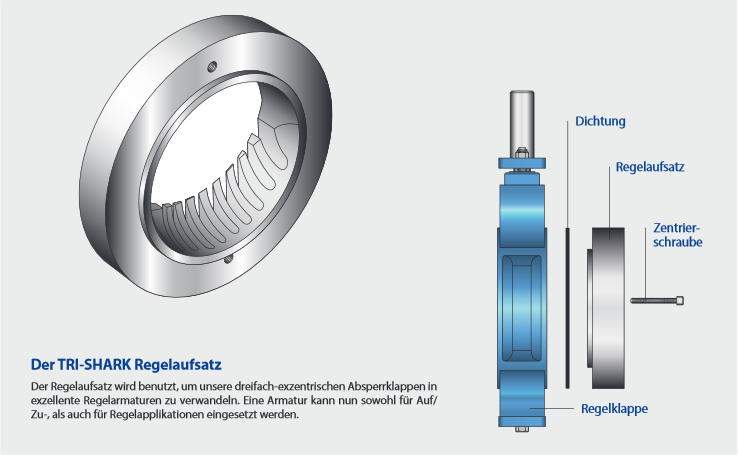

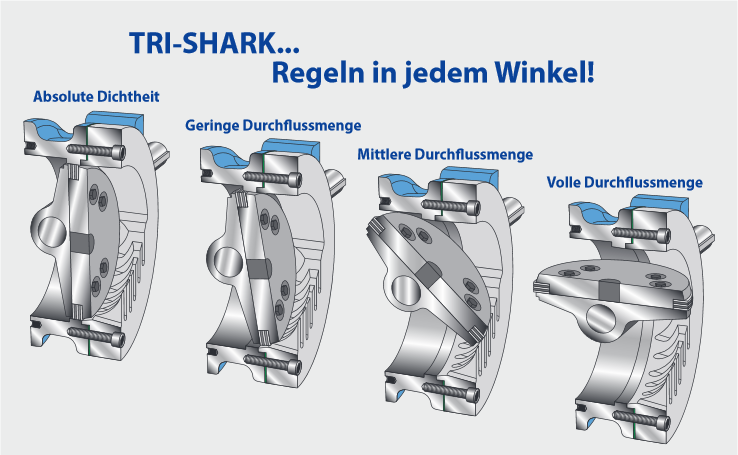

Operating principle

The three-eccentric valve design ensures minimal friction and tightness even at high temperatures and pressures.

100% Regulation

100% airtightness

Parameters:

Nominal diameter:

from DN 80 up to DN 1600

Nominal pressure:

10-100 bar

Work temperature:

from -40˚С up to +550˚С ; with the possibility of higher temperatures upon request

Body materials:

carbon steel or stainless steel

Gasket materials:

• Metal in metal

• Metal in stainless steel lamella and graphite

• Metal in stainless steel lamella and Teflon

Assembly:

• Between flanges – Wafer type or Lug type

• On flanges according to DIN EN 558/F4, ISO 5752/F16, ANSI B16.10

• On welding

Applications:

For petrochemicals and gas production: platforms, refineries, fuel storage and transit, Chemical and other industries: process, refrigeration, flue gases, steam, etc. power plants and district heating: hot water, steam and processes

Advantages:

• Wide range of sizes: from DN80 to DN1600

• Regulating and locking function

• Maximum working temperature up to 550˚ C with the possibility of higher parameters.

• Tri-eccentric design, guaranteeing a long service life.

• Saddle with a special construction that protects it from contamination and injury.

• Replaceable saddle.

• Hermeticity in both flow directions (the valve does not have a specific installation direction) with tightness level “A” according to DIN EN 12266-1 (1 according to DIN 3230) – zero leakage in both directions

• Seal type: metal to metal

• Self-centering disc, compensating for linear expansions.

• Anti-static design – it is not possible for sparks to form in the valve.

• Special construction of the shaft bearings, which prevents its distortion.

• Fire safety according to API 607 (FIRE SAFE) – remains airtight in case of fire

• Environmental tightness control according to TA-Luft 1 and 2

• explosion safety according to ATEX CEII2G Eexn IIC T6