Products

Products

Loose rubber lined centric butterfly valves – Desponia® и Desponia® plus – InterApp

Main Futures:

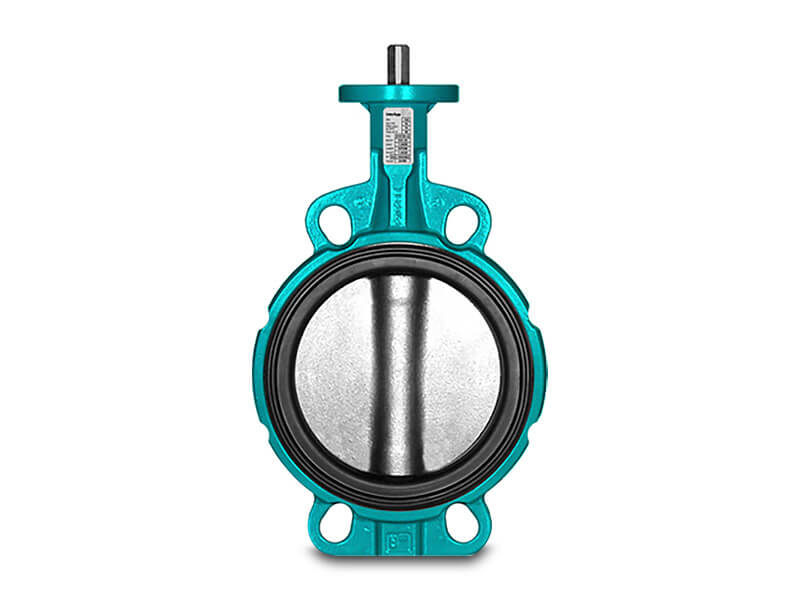

Centric “Butterfly” valves are used for ON/OFF and flow regulation. Their principle of operation (opening and closing a quarter turn by means of a disk mounted on an axle) resembles that of ball valves, but their main advantages over them are lower cost and less weight, which eliminates the possible need for additional installation on supports.

Type of body:

- Wafer – between flanges.

- Lug – between flanges with threaded LUGs. It is ALSO possible to dismantle the pipeline from one side without the need to remove the valve itself.

- U – shaped – double flanges

Dimensions:

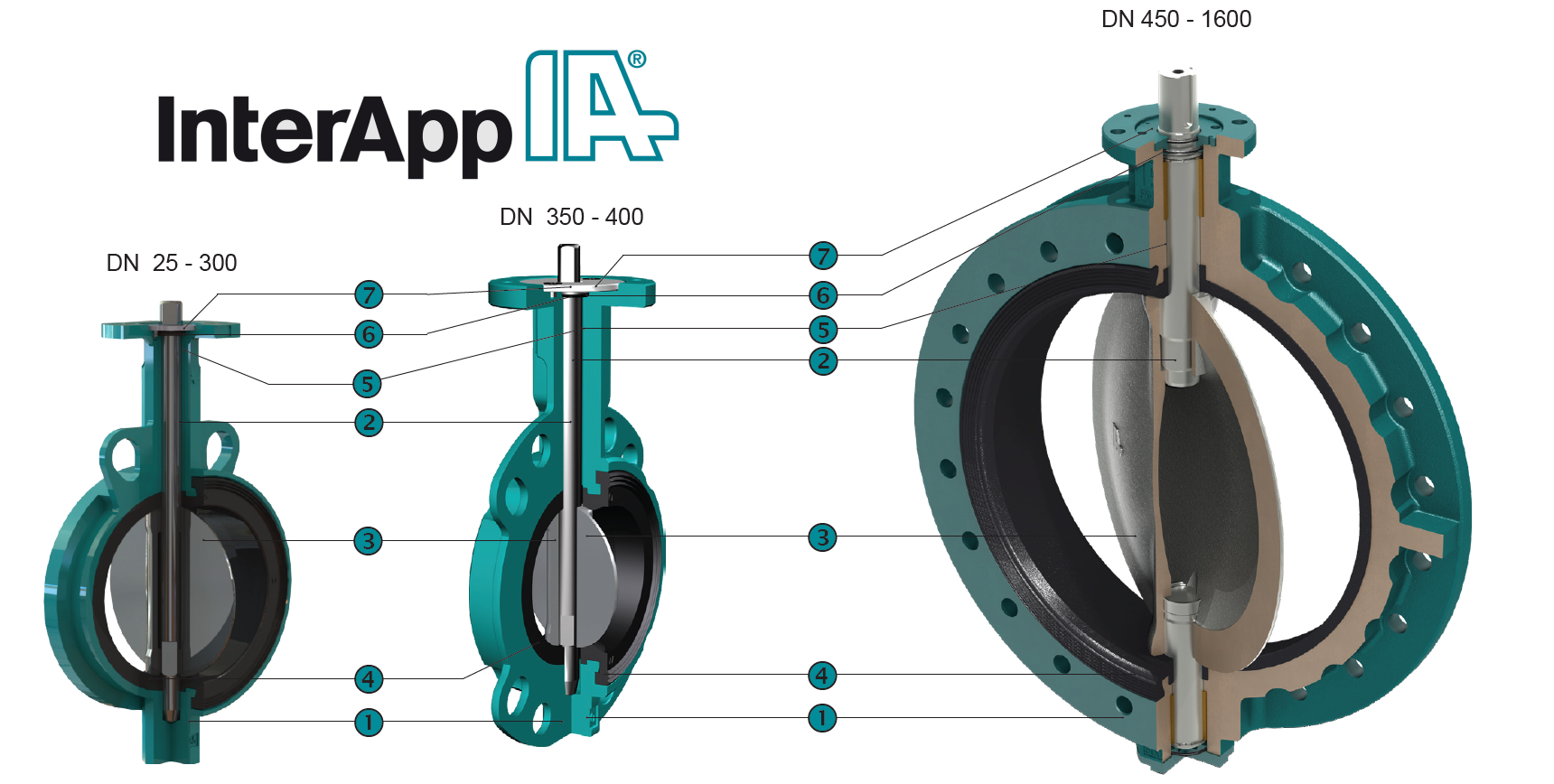

Nominal diameter:

- DN 50—1600 (Desponia®)

- DN 25—600 (Desponia® plus)

Nominal pressure:

- From 10 up to 16 бара (Desponia®)

- Up to 20 бара (Desponia® plus)

Operating temperature: Depends on the sleeve and disc materials used

Materials:

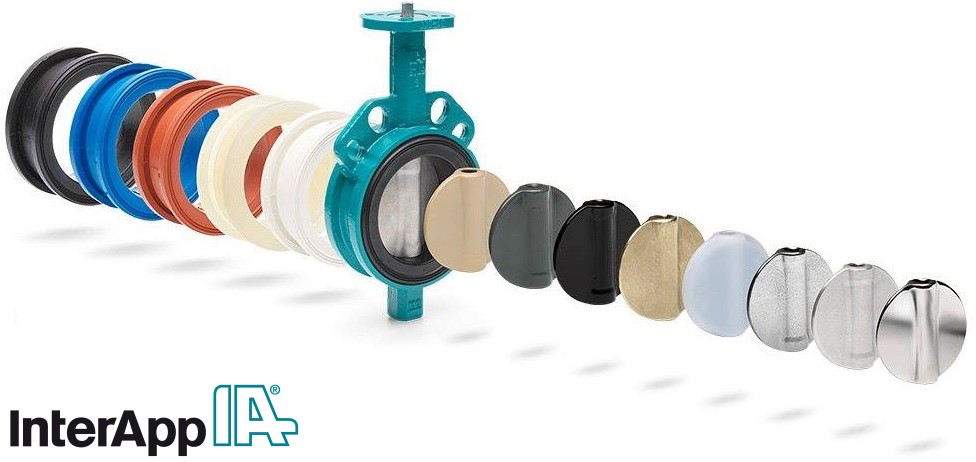

Body : cast iron GG25, Ductile Iron GGG50, Carbon Steel A216 WCB, Stainless Steel SS316, Polypropylene

Disc: Ductile Iron GGG50, Stainless Steel SS316, PTFE lined Stainless Steel SS316, Uranus B6, PVC, Polypropylene, etc.

Sleeve – NBR, EPDM, FKM (Viton®), Hypalon®, Silicone, Food Grade Silicone, PTFE, etc.

Operating:

Manual with a handlever

Manual with a gear box

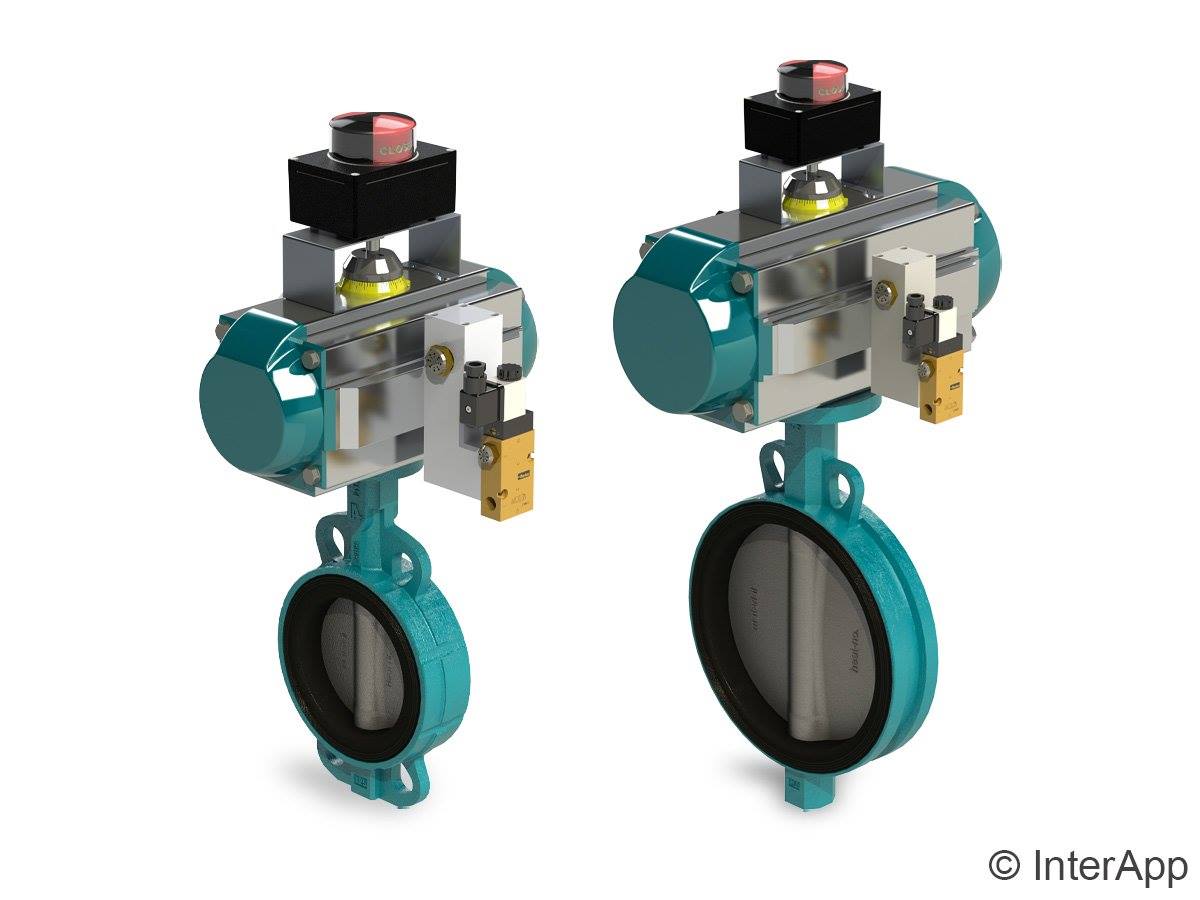

Automatic, with pneumatics – Doube acting or single acting with spring

Automatic, with electric drive

Applications:

For water, gases, chemical media, abrasive applications, processes, food industry

Advantages:

• Low price

• low own weight – easy to install

• massive sleeve, guaranteeing high hermeticity

• possibility of placing insulation

• possibility of automation

• easy sleeve replacement

Catalogue – InterApp DESPONIA

IOM – InterApp DESPONIA

Brochure – InterApp