Products

Products

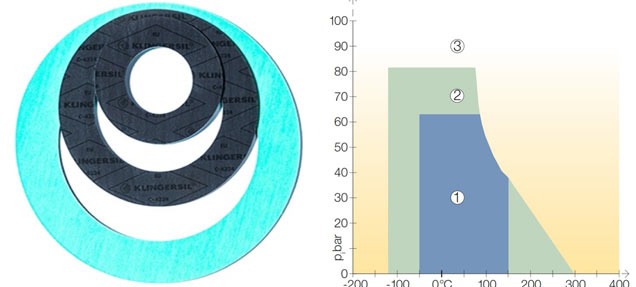

Klinger Sil C 4324

Universal seal for high pressure with a wide range of application and good resistance to crushing

Composition and application:

A combination of synthetic high quality fibers bonded to NBR.

Resistant to hot water, steam, oils, hydrocarbons, gas and many other chemicals.

Certificates:

DIN-DVGW

DIN-DVGW W 270

Elastomer-Guideline

German Lloyd

SVGW approval

Technical data:

Compressibility ASTM F36 J: 10%

Recovery ASTM F 36 J min: 55%

Stress relaxation DIN 52913 ( 50 MPa 16h/300˚C): 20 MPa

KLINGER cold/hot compression 23˚ С: 10%

KLINGER cold/hot compression 300˚ С: 25%

Tightness DIN 28090-2: 0,03 mg/s.m

Thickness increase ASTM F 146 ( Oil JRM 903: 5h/150˚C): 5%

Thickness increase ASTM F 146 ( Fuel B: 5h/23˚C): 10%

Density: 1,85 g/cm3

Thickness: 2 mm

Non-stick coating of sealing materials:

All KLINGER Sil sealing materials have a special non-stick coating with low adhesiveness, which allows easy separation of the finished gaskets from the installation site. Graphite coatings are also made to order.

KLINGER Expert – A computer program supporting the selection of material, the size of standard fittings and the calculation of the bolt tightening moment. Translated into Bulgarian

Dimensions of the standard sheets:

1500 mm х 1500 mm (available on stock)

2000 mm х 1500 mm ( on request )

Thickness:

1 mm, 2 mm, 3mm ( available on stock )

Other thicknesses (on request)

Production of ready-made garnishes:

POLIMAT Ltd. offers selection of the appropriate material depending on the parameters of the working environment and production of ready-made garnishes according to the customer’s specification.