Products

Products

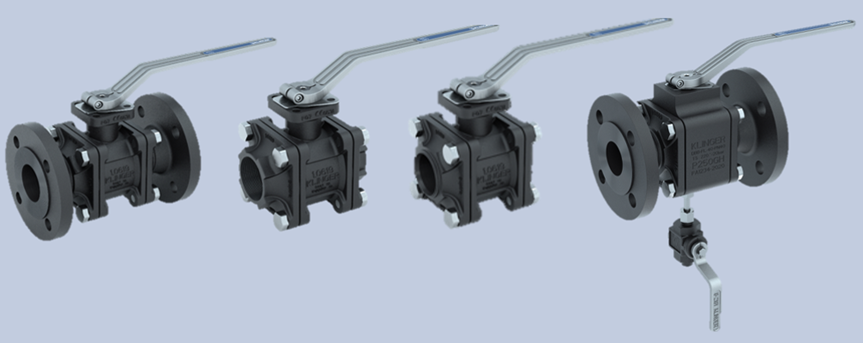

3-piece body ball valve – KLINGER BALLOSTAR® KHA 2022

Description

Fluid leakage is a major problem in every installation and every manufacturing plant. Adverse consequences can be a negative impact on the environment, as well as a forced shutdown, which on your part leads to financial losses. It is imperative that the sealing system of the fitting be reliable and perform its sealing function qualitatively. With the KLINGER Ballostar® KHA, this is possible in many ways. The ball valve’s unique sealing system will help keep any issues at bay and keep your processes running smoothly.

Advantages of sealing element design KLINGER KHA

The unique sealing system of the ball valve series KHA offers striking advantages which affect the service life, operational readiness, reliable function, operating costs, maintenance costs and tightness. Regardless of which sealing element version is used in a KHA ball valve, there are advantages common to all versions:

– No coil springs – preloaded diaphragm

– Robust design – no relaxation

– Flexible & automatic pressure relief

– High temperature abilities

– Dynamic sealing chamber

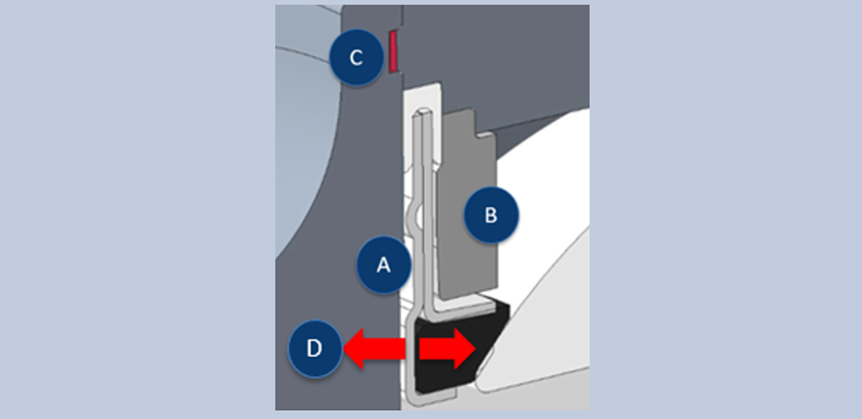

KHA NEW generation: sealing elemets – no coil springs

The prestressed diaphragm springs (A) ensure the contact of the seat with the ball. The fluid and possible impurities can circulate behind the diapgram springs. There is no retention zone and no clogging ( Insensitive to impurities). The support ring (B) protect the sealing element against possible mechanical loads. An additional C4430 gasket (C) on housing pitch ensures increased tightness to atmosphere.

Sealing elements – diaphragm springs

The absorption area of the medium pressure is not limited to the ball area, but encompasses the entire sealing element. In the event of an increase of differential pressure, the additional forces increase as well – the preloaded diaphragm springs (D) which press against the ball are subsequently relieved and service live further improved

Robust design – no relaxation

The multi part design of the sealing element combines elastic and robust properties. The seal ring is chambered from 3 sides (protected) by cover and support disc for high stability and to avoid plastic deformation. For higher mechanical resilience, an additional support ring is used (support ring is not necessary when using one part sealing element design). This structure is also appropriate for pressure and temperature changes with no relaxation and perfect sealing characteristics.

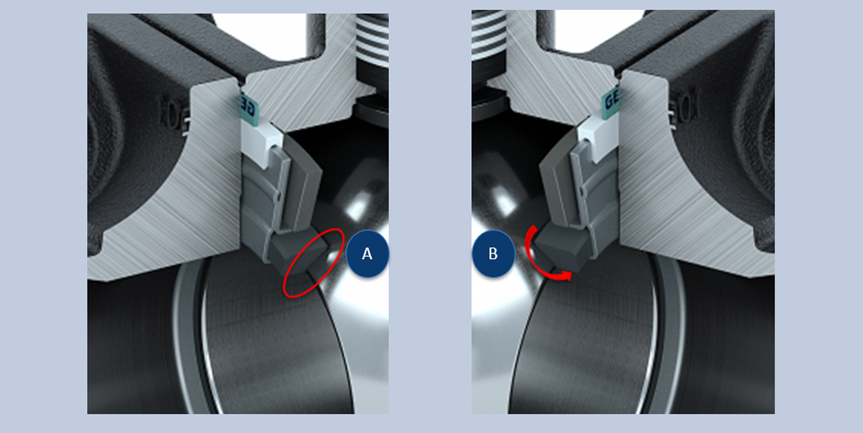

Flexible design – automatic pressure relief

Due to the spring loads of the sealing elements and the position of the seal ring on the ball surface, possible particles in the media which can lead to damages on the ball will be absorbed (A). If the cavity pressure is higher than the spring force of the downstream sealing element, this element will lift off the ball and drain the cavity pressure in the pipe line (B). After that, the sealing element will move back in original position. This effect is only possible with the elastic design of these sealing elements.

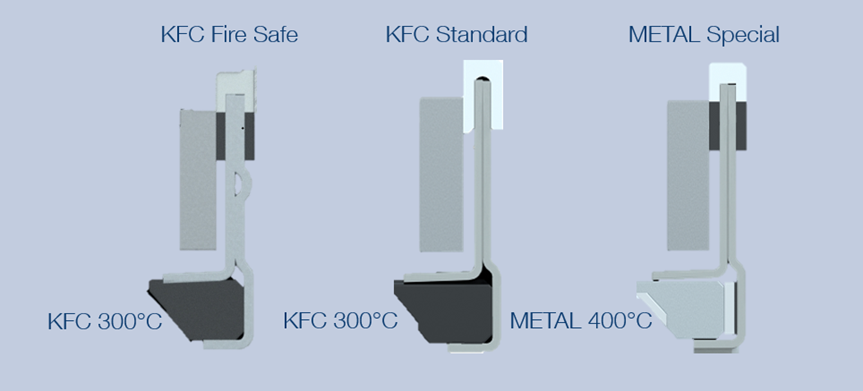

High temperature abilities

All sealing elements with KFC seal ring (= 75% PTFE and 25% graphite) in standard or fire safe version are valid up to 300°C service temperature (in comparison: PTFE sealing elements up to 200°C and viton sealing elements up to 150°C). The metal special sealing element can be used until 400°C service temperatures.

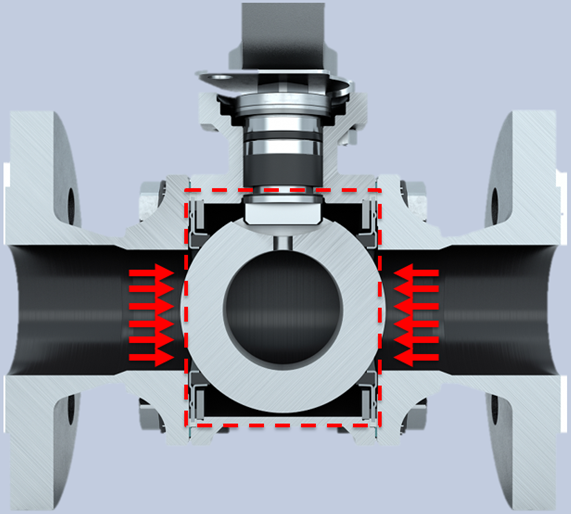

Dynamic sealing

The Ballostar KHA ball valve utilizes spring loads in two sealing elements for the function of the valve which results in an sealing chamber in which the loads of the sealing elements simultaneously work bidirectionally. When connecting the flanges with the centre piece the forces of the preloaded springs are released and press the sealing rings to the ball. This happens irrespective of whether there is fluid pressure or not. The forces still act at very low differential pressures and vacuum.

Technical details

Nominal diameter:

from DN 10 mm up to DN 150 mm

Nominal pressure:

10 bar.,16 bar.,25 bar.

40 bar., 63 bar. and 100 bar.

Working temperature:

from -196ºC up to 400ºC

Materials:

Cast iron:GG-25, Carbon steel: 1.0619 and Stainless steel: 1.4408.

Материал:

Чугун:GG-25, Въглеродна стомана: 1.0619 и неръждаема стомана: 1.4408.

Connections:

- On flanges;

- Welding ends;

- Threaded ends;

- Stem extension;

- Double block and bleed.

Accessories:

Actuators (Pneumatic, Electric) stem extension for low temperature applications, locking device and etc.

Advantages

● Modular assembly system with 6 types of sealing elements

● 3 types of spindle seals.

● Two-way self-sealing valve.

● Two-way self-sealing valve.Antistatic performance.

● Membrane seals.

● Ability to automate.

● Does not require maintenance.

● Modular assembly system depending on customer needs.

● ISO flanges.

Brochure – 3 piece body ball valves KLINGER KHA NEW model 2022