Products

Products

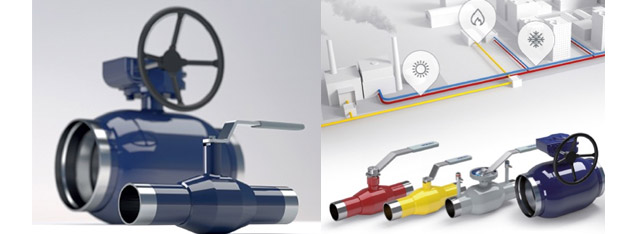

Steel ball valves, full bore – Vexve OY – Finland

Description:

- All welded construction

- Light weight

- Easy to isolate

- Space saving design

- Easy to install

- Easy to operate

- They do not need maintenance

- Long service life

- General two-way tightness according to EN 12266-1 rate A

- High Kv values (minimum pressure losses)

- High-strength materials capable of withstanding variable water qualities

- Stainless steel sphere

- Double fixed (bearing) sphere (for sizes ≥ DN 600)

- Spring pressing of the PTFE seal to the sphere

- Spindle sealing with two O-rings

- Designed and certified in accordance with EN 488: 2011

Dimensions:

- In sizes from DN 10 to DN 800

- With welded connections (recommended) according to EN (DIN) and GOST

- Also available in flanged and threaded connections · full bore and reduced bore designs

- With manual lever, manual transmission, electric or hydraulic actuator

- With discharge valve and mounting bracket (sizes ≥ DN 600)

- Nominal pressure: PN16 bar/ PN25 bar/ PN40 bar

- Operating temperature: From -20ºC to +200ºC

Materials:

Carbon steel and stainless steel

Special performance:

– Insulated faucets

– Ball valves with extended spindles

– Taps for cutting under pressure

– Regulating ball valves with “V-port”

– Steam and condensate taps

Advantages

● Safe to use and reliably sealing

● No service

● The sphere and spindle are made of stainless steel

● Specially profiled saddles provide double sealing of the sphere

● Reliable sealing system

● Spindle sealing with high-quality elastomer O-ring

● O-ring replaceable

● A special spring secures the sphere in any position

● The working position of the sphere can be determined even with the handle removed

Catalogues: